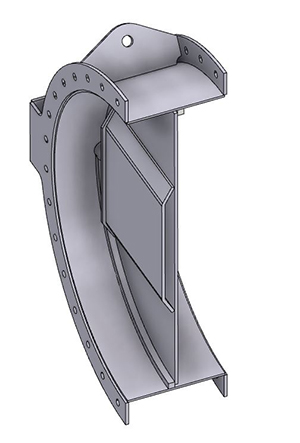

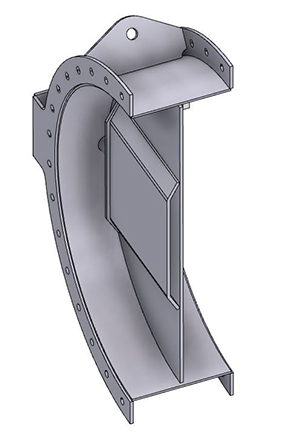

ISOLATION DAMPER

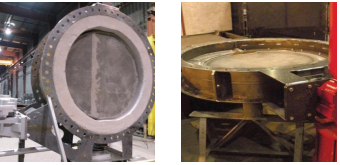

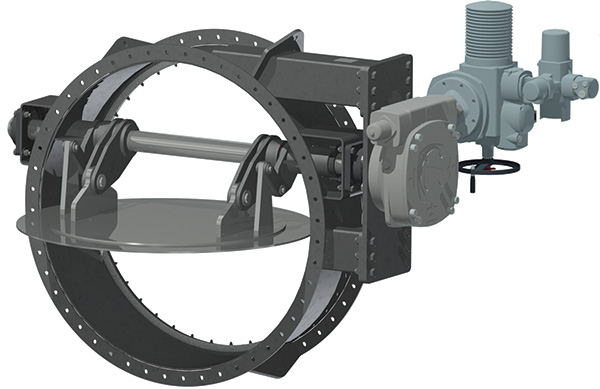

Our Hot Frame Guillotine design is the best commercial and technical fit for isolation applications where reliability is a concern.

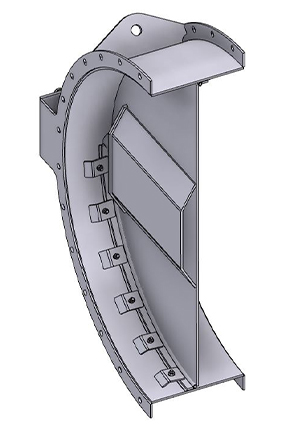

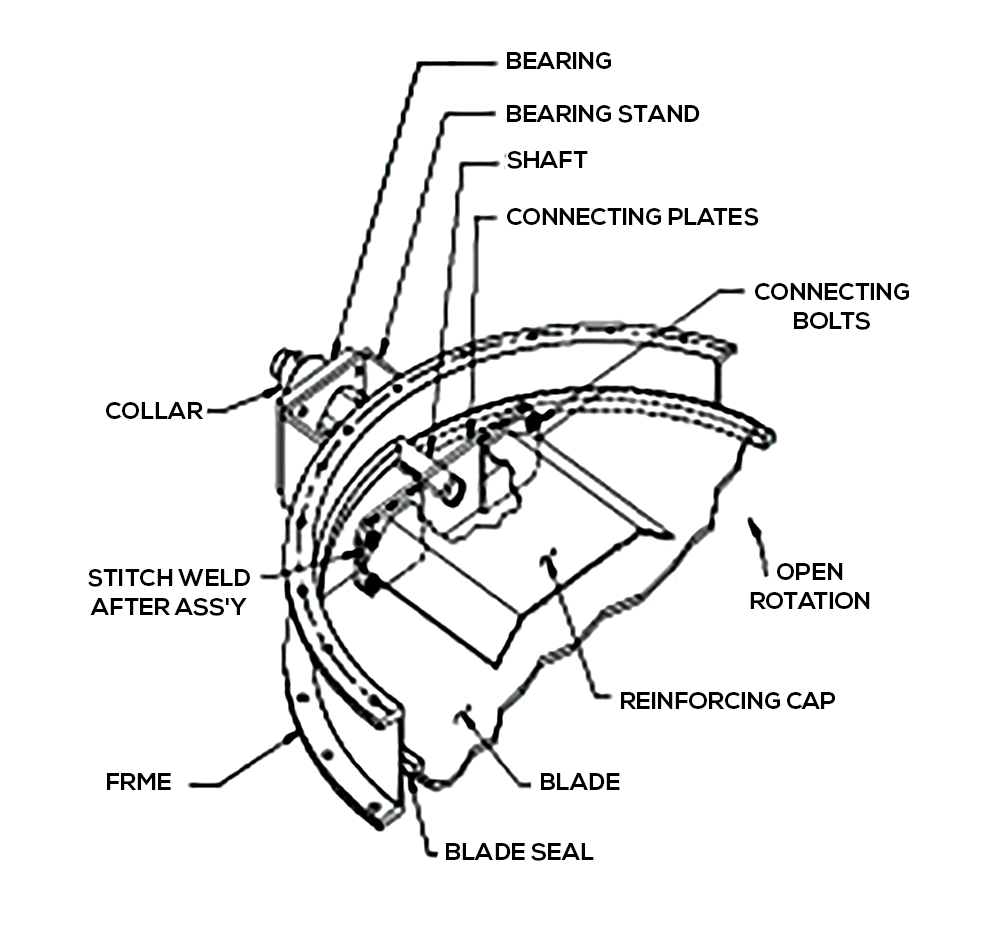

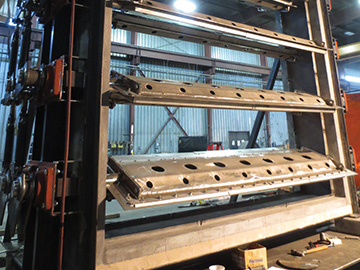

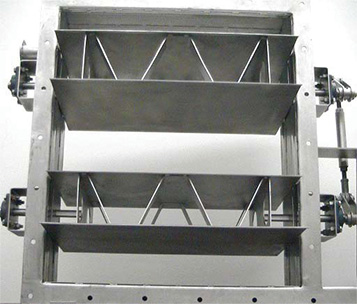

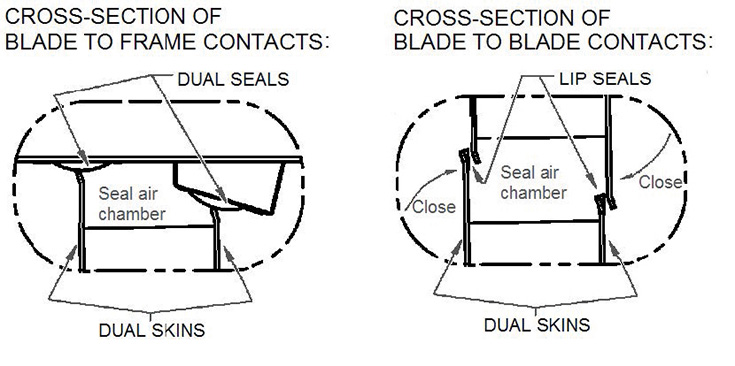

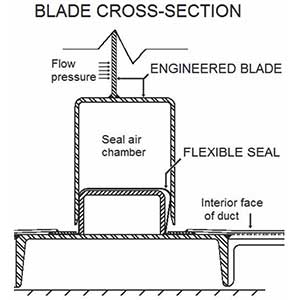

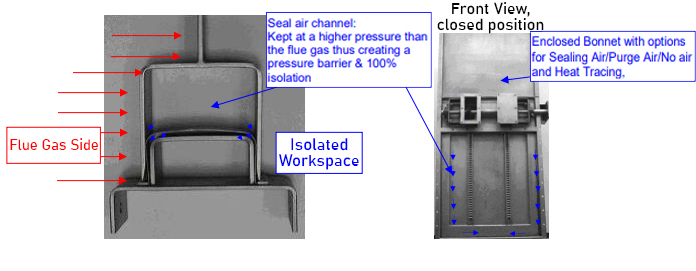

Bachmann Dampjoint engineers have been designing and supplying the unique Hot Frame Guillotine to the industry for decades. This proven, rugged design is specifically tailored for isolation applications where reliability and performance are crucial. Our Hot Frame Guillotine damper has two key features: our worryfree flexible-seal combined with our engineered blade design. These two innovations completely eliminate the need for a frame seal cavity and ensure dual seal contacts within the duct. This also allows seal components to be kept entirely inside the duct, where the flue gas keeps them hot – hence the “hot frame”.

Benefits:

- 100% isolation with seal air

- Self cleaning blade seal

- No risk of dust accumulation

- Mitigation of corrosion issues

- Increased seal life and durability

- No bottom frame purge required

- Reduced capital, operating, shipping and field assembly costs

- Fully isolated bonnet

- Low pressure drop

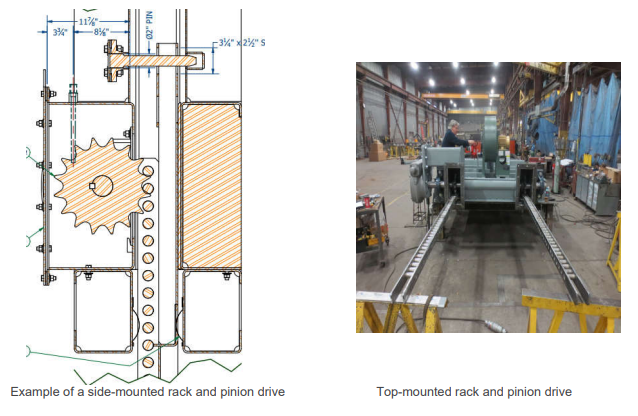

- Self-cleaning drives with superior reliability

These features have significant benefits:

- 100% isolation – Indeed, when seal air is used, our Hot Frame Guillotine damper allows 100% isolation. If no seal air is used, 99.5% isolation can be achieved.

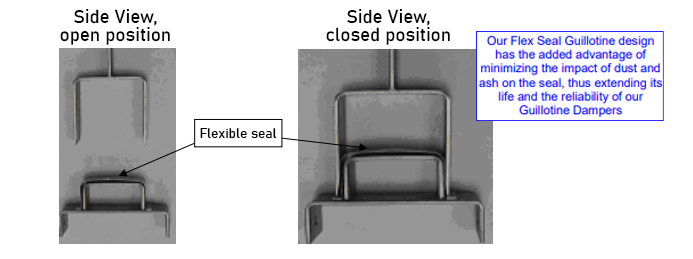

- Self-cleaning blade seal – The dual knife blade end design allows dual seal contact whiler emoving any accumulation of dust, thus guaranteeing isolation integrity.

- No risk of dust accumulation – There is no seal cavity where dust can accumulate.

- Mitigation of corrosion issues – There is no “lower temperature” seal cavity where acid condensation can occur.

- Increased seal life and durability – Our blade seals are engineered for a smaller 1/8” deflection, versus the large forced deflection of 3/8” to 3/4” in conventional guillotine flat plate blade designs. This reduces cycle fatigue stress and increases the lifespan of the seals. Also, mitigation of dust accumulation and acid condensation drastically reduces seal wear.

- No bottom frame purge required – Since our Hot Frame Guillotines do not have a bottom frame seal cavity, no purge, extra ducting or additional maintenance are required.

- Minimization of cleaning, maintenance and replacement costs – With reduced wear from corrosion and dust accumulation, our design is truly worry free!