DUCTING EXPANSION JOINTS

The most versatile combination of flexible element and hardware, covering the widest range of applications in the industry. THE ONE SOLUTION to most fabric expansion joint requirements, 100% factory assembled.

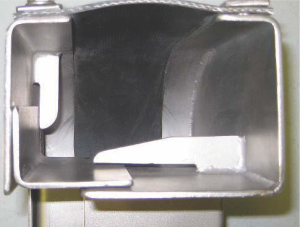

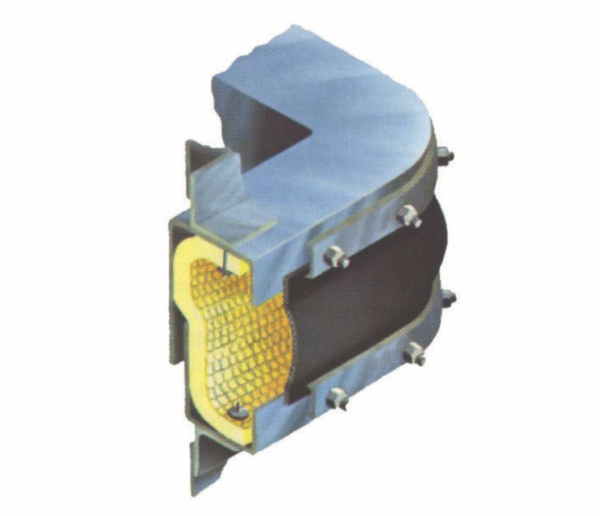

For applications where abrasive and corrosive protective liners are required and/or maximum protection of flexible element and/or in layered composite belts used attemperatures of 450ºF – 2300ºF.

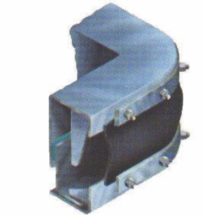

When vertical, horizontal & lateral movement are present

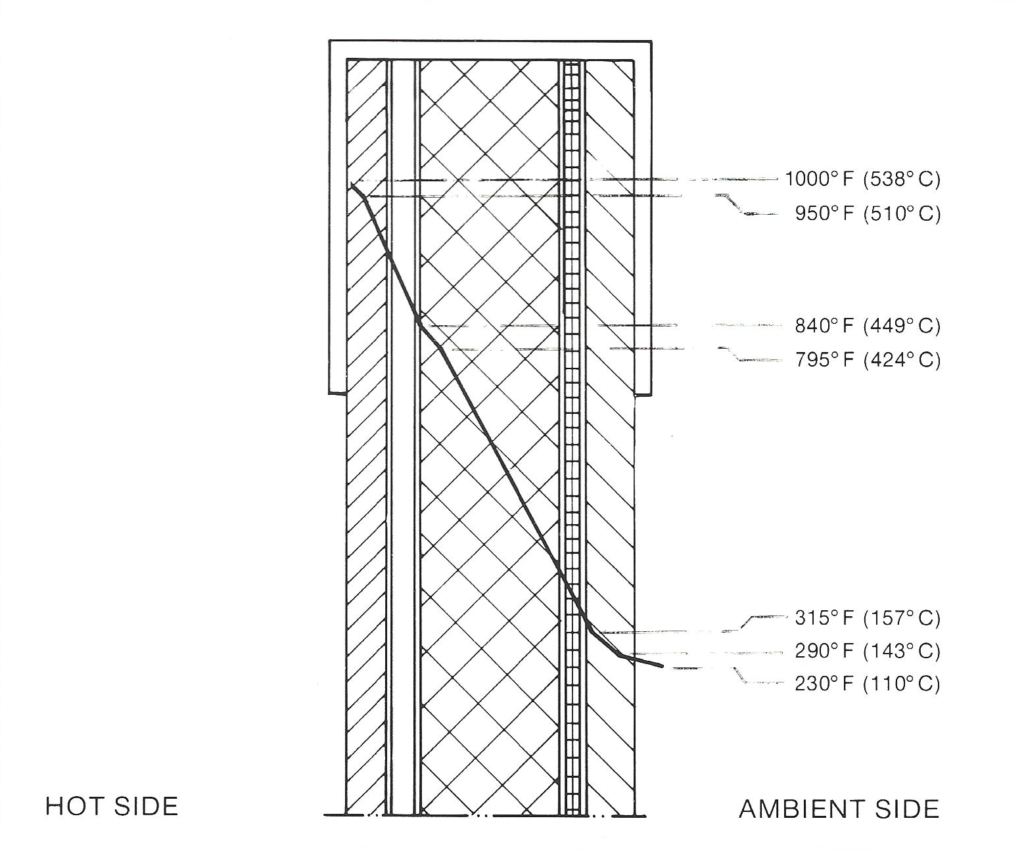

- Reliable Performance at High Temperature

- Large Movement Capability

- Wide Selection of Flexible Elements for full Temperature Range

- Rectangular or Round Configurations

- 100% Shop-Assembled for easy field installation,

bolt in or weld options - Minimal Deflection Forces

- Wide Selection of Hardware and Metallurgy